Post apprenticeship I worked for some twelve months shunned by the other workers before deciding to move back home and take up a position in a local carpet factory. Actually, I worked in the back office of the sales department.

I enjoyed the work more especially so since I was free of trade union ethos and enjoyed the company of work associates who came from a different walk of life to that I had been used to. I made friends with one particular person about my own age who was public school educated and was very ‘posh’ but for whatever reason he seemed to enjoy my company and we got on quite well together. I learned quite a lot about carpet manufacture and could well have acquired a coveted job in the front office. I seemed to be well liked both in the office and on the factory floor where I was able to roam freely as part of my work. I took a course on salesmanship, but engineering and particularly electrical engineering was my first love, so much so that an advertisement for a position with a major international electrical engineering company offering training in control engineering proved so attractive that I decided to apply.

The interview proved to be a whole new experience for me. I sat in front of a panel of senior engineering departmental heads who plied me with various technical questions which were quite outside my work experience but fortunately within my academic studies. Obviously, I must have impressed the panel for a position was offered me which involved training and experience in application and control engineering whereas my previous experience was in installation and distribution, so I left home and took up lodgings for the second time.

I lodged with a brethren family and started my training at the English Electric Company in Stafford initially in the drawing office school. The school operated a staggered entry system which meant that the student could work at his own pace through a series of exercises. I had already studied technical drawing so was able to complete the exercises quite quickly so work was brought in from the switchgear drawing office and I was eventually transferred there where I could have settled down. However, my aim was to move into the Metal Industries Division working as an application engineer and this I did starting in the technical writing section producing manuals for the various steelwork projects the division was engaged on. I really enjoyed this work as I was able to learn quite a lot and in detail about a whole variety of equipment and control systems that comprise a comprehensive rolling mill complex. I was able to spend time discussing design details with specialist engineers, all experts in their own particular field.

I could visit the shop floor without hindrance viewing equipment at various stages of manufacture.

I had full access to archives of completed projects all extending my knowledge. In many ways it was a great learning experience and the actual task of writing manuals like making detailed notes of what I was learning. Following this I graduated to writing commissioning material for engineers who would eventually commission the plant on site and tune the associated control systems for optimum performance. I also did some tutoring one-on-one and on-site trouble shooting.

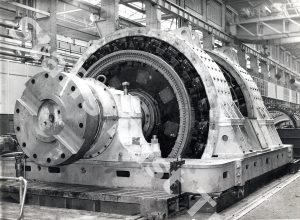

These site visits got me out of the office and into the real world of work. Invariably I was able to quickly solve a problem while under intense stress since a mill working at reduced capacity or completely down would be losing money at an alarming rate. On one occasion I was called out to find a group of electrical and production engineers, managers of various sorts and their respective heads of department awaiting me. The plant had been running at very much reduced capacity for three days having knock-on effects elsewhere within the overall company production facility. No one had been able to solve the problem including those who were responsible for the daily maintenance of the plant. Fortunately, I was quite familiar with the plant having previously commissioned it, so I stationed myself at the supervisory panel, much to the frustration of the chief production engineer, simply scanning a mass of instrumentation as the mill continued rolling steel at a reduced rate. Only one slab was being rolled every four minutes so eight minutes for two slabs to pass through with me seeming doing nothing at all must have seemed like an eternity. Having made my decision as to what the problem probably was, without a word, I simply walked away and down the vast motor room followed by the group of senior personnel. I had been taught to think through simple possible solutions first and there, directly below the vast rolling mill, double armature twin drive motors there was the problem staring me in the face. Someone had left open a knife-switch used to select which motor, top or bottom, was being used to obtain a reading of actual current being draw. The signal was used to limit the maximum level of current the drive could draw during the rolling process. In the event of this particular control function failing excess current would result in a huge stand-alone direct-current circuit breaker opening with such force that, not only would one not wish to be near them when opening under fault conditions but after three operations they would need to be expertly checked over and re-calibrated and this particular breaker had already operated under fault conditions twice! I must admit to relishing every moment silently standing there listening to the whirl of these vast motors directly above my head as they accelerated and decelerated during the rolling process. I was waiting for an opportune moment to throw the switch closed during the interval between slabs when the drives would be stationary. Having done so I uttered just three words to the assembled company; “thrash the mill”! Apart from the chief production engineer I don’t think anyone else thanked me, they just melted away somewhat embarrassed I suspect. I am sure there would have been a high-level inquiry about why the switch had been left open and who had done so, but that was the last I heard of the matter.

I credit the Lord for moments of inspiration experienced in situations similar to the above.

The metal industries division was in the forefront world-wide in cutting-edge technology in the steel industry. We generally regarded ourselves as being the crème al la crème.

The division had won the contract for a major, state of the art, semi-automatic, hot strip rolling mill complex at Motherwell, Scotland; Ravenscraig. I had the privilege of being invited to commission the scale breaker, reversing roughing mill and flying shear and associated ancillary and auxiliary equipment that fed the six-stand continuous strip mill. This was the first of many mills that I commissioned and was an exciting and satisfying development in my career. I enjoyed the sheer scale and complexity of the equipment involved, the sight and smell of red-hot metal being processed, and the associated noise all added to the experience. Later I moved into a section which specialised in ‘Turn-key’ projects for the metal industries as an Application Engineer. I gained experience in water treatment plants, ventilation systems, sound systems and specialist instrumentation development through an associate EEC company before finally moving into another section specialising in material handling. One of the most satisfying assignments in this last move was to be involved in a study of the computerisation and automation of the emerging technology for handling and storage of shipping containers due to their rapid increase and use for moving freight around the world.

During my time at English Electric, I bought my first house putting down a seventy five percent deposit with the intention of paying off the rest within five years. Marriage however intervened which meant that I did not achieve this aim and our first child was born some three years later followed by a second two years after the first.